How to Improve Fibre Optic Quality Control with the Optical Fibre Diameter Analyser

How to Improve Fibre Optic Quality Control with the Optical Fibre Diameter Analyser

Blog Article

Just How an Optical Fibre Diameter Analyser Boosts High Quality Control in Fibre Manufacturing

The integration of an Optical Fibre Diameter Analyser right into Fibre manufacturing processes represents a substantial development in quality control techniques. By providing real-time, precise dimensions of Fibre sizes, this modern technology deals with the crucial demand for consistency in production standards. With its capacity to swiftly recognize discrepancies and timely corrective steps, the analyser not just boosts product reliability but likewise adds to total functional effectiveness. As markets progressively prioritize top quality and compliance, recognizing the full effect of such innovations ends up being essential. What ramifications could this have for the future of Fibre manufacturing?

Importance of Fibre Diameter Dimension

Exact dimension of Fibre Diameter is essential in the field of optical Fibre technology, as it straight affects the efficiency and dependability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying ability, depletion, and general transmission efficiency. Precision in gauging Fibre Diameter guarantees that the optical residential properties are preserved within specified tolerances, which is essential for ideal signal stability.

Variations in Fibre Diameter can result in increased losses due to spreading and modal diffusion, impacting the quality of information transmission. In high-speed communication systems, such discrepancies can cause substantial deterioration of signal quality, bring about information errors and reduced efficiency. Constant Fibre Diameter is essential for compatibility with adapters and splicing innovations, which are indispensable components of Fibre optic networks.

Quality control procedures in Fibre manufacturing heavily count on precise Diameter measurements to make certain compliance with sector standards. By applying robust dimension techniques, makers can enhance product integrity, reduce waste, and boost overall system efficiency. Thus, the relevance of Fibre Diameter dimension can not be overstated, as it works as a keystone in the development of optical Fibre modern technology and its applications in contemporary interaction networks.

Exactly How the Analyser Works

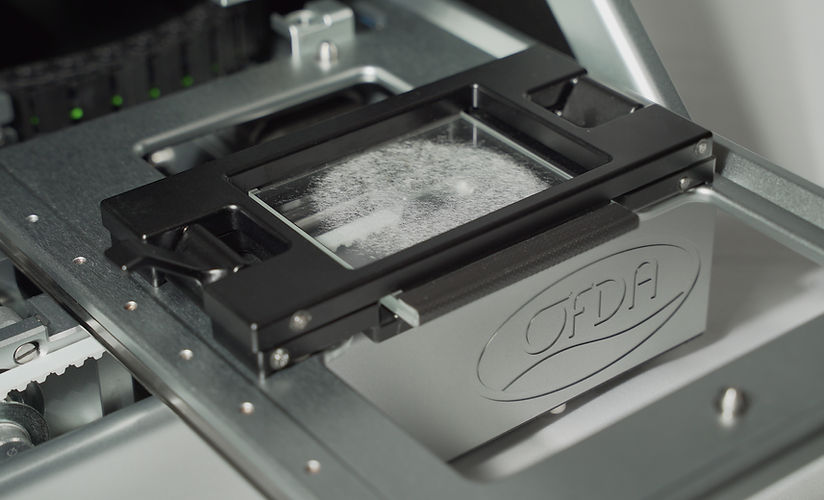

The efficient dimension of Fibre Diameter relies upon advanced analytical strategies that guarantee precision and dependability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and advanced photo handling algorithms to accurately examine the Diameter of fibers as they are produced

At first, a laser beam of light is routed at the relocating Fibre, creating a cross-sectional shadow. The analyser catches this shadow utilizing high-resolution electronic cameras positioned strategically along the production line. The caught pictures are after that refined in real-time to establish the Fibre's Diameter with remarkable accuracy.

The system uses advanced algorithms that represent different aspects, consisting of variants in light strength and ecological conditions, to improve measurement dependability. It can discover minute modifications in Diameter, such as changes that may occur during the manufacturing process.

Furthermore, the analyser is capable of handling multiple fibers concurrently, boosting throughput without endangering accuracy. By offering instantaneous responses on the Diameter, the Optical Fibre Diameter Analyser plays a vital function in maintaining rigorous high quality control requirements, ensuring that the end product meets sector specs and customer needs.

Benefits of Real-Time Surveillance

While standard methods of monitoring Fibre Diameter commonly involve taxing post-production checks, real-time tracking considerably boosts the effectiveness and quality of optical Fibre production. optical fibre diameter analyser. This positive approach enables manufacturers to determine deviations in Fibre Diameter as they occur, instead of waiting until manufacturing is complete to examine top quality

By constantly gauging the Diameter throughout production, makers can ensure that the fibres fulfill strict specs, leading to minimized irregularity and improved consistency. Real-time surveillance also allows prompt corrective actions to be taken, lessening waste and preventing defective fibres from getting in the supply chain.

Furthermore, this innovation facilitates boosted information collection and analysis, offering insights right into manufacturing fads and potential areas for enhancement. Such data-driven decision-making empowers makers to maximize procedures and preserve high requirements of quality assurance.

On top of that, real-time monitoring fosters a society of continual renovation within the production environment. Workers are a lot more involved when they can see the influence of their operate in real-time, resulting in increased responsibility and a dedication to excellence. On the whole, the application of real-time surveillance systems in optical Fibre manufacturing converts to exceptional item top quality and raised client complete satisfaction.

Influence on Production Effectiveness

Implementing optical Fibre Diameter analysers considerably boosts manufacturing performance by improving the manufacturing process. These tools promote constant tracking of Fibre Diameter, permitting suppliers to discover discrepancies in real-time. By identifying incongruities without delay, assembly line can be changed rapidly, minimizing downtime and lowering the probability of creating defective items.

Moreover, the integration of these analysers right into the manufacturing workflow makes it possible for much better resource appropriation. With precise Diameter dimensions, operators can maximize material use, making sure that resources are not lost on flawed fibers. This precision additionally adds to less ditch and rework, inevitably lowering manufacturing costs.

The automation given by optical Fibre Diameter analysers reduces dependence on manual examinations, which are vulnerable and commonly taxing to human error. Therefore, employees can concentrate on even more calculated jobs, enhancing total productivity.

Additionally, the information generated from these analysers can notify procedure improvements and assist in far better decision-making. By analyzing patterns in Fibre Diameter variations, suppliers can implement positive actions to enhance production methods and keep regular quality. In summary, optical Fibre Diameter analysers play an essential role in increasing manufacturing performance, leading to better outcome and boosted productivity.

Case Researches and Success Stories

Throughout different fields, instance studies highlight the transformative impact of optical Fibre Diameter analysers on production processes. One prominent example is a leading telecommunications company that faced challenges with irregular Fibre sizes, bring about increased rejection rates. By integrating an optical Fibre Diameter analyser, the company achieved real-time monitoring of Fibre measurements, causing a 30% decrease in issues and substantial price financial savings.

Additionally, a study organization concentrating on sophisticated products used optical Fibre Diameter analysers to improve their more info here experimental procedures. The analyser's capability to supply detailed understandings into Fibre uniformity enabled the growth of innovative products with improved my latest blog post performance features.

These success stories highlight the important function of optical Fibre Diameter analysers in improving top quality control, improving manufacturing performance, and driving development throughout varied industries.

Final Thought

In final thought, the Optical Fibre Diameter Analyser plays a critical role in enhancing quality control within Fibre manufacturing. As shown via numerous instance research studies, the analyser verifies vital for accomplishing remarkable product quality in Fibre production.

The execution of optical Fibre Diameter analysers allowed for rigorous high quality control, making certain that the created fibers met exacting sector standards.In get redirected here verdict, the Optical Fibre Diameter Analyser plays a crucial role in boosting quality control within Fibre production.

Report this page